Additive Manufacturing

Cold Spray Additive Manufacturing

HAMR Industries has acquired a WarpSPEE3D cold spray additive manufacturing (CSAM) system, capable of large format prints using a variety of metal and composite systems. Interested in exploring cold spray for part generation or repair, but not sure if it will work for your application? Contact us and let us help answer these questions!

Capabilities include:

High pressure cold spray

Numerous metals and alloys of Al, Cu, Fe, Ni (Inconels), Ti, Nb, and more

Oxide, carbide, boride, and nitride cermet composites

Large format prints with a 1m Ø x 0.7m build volume

Build rates in excess of10 kg/hr or1 L/hr

Radomes, Windows, and Apertures

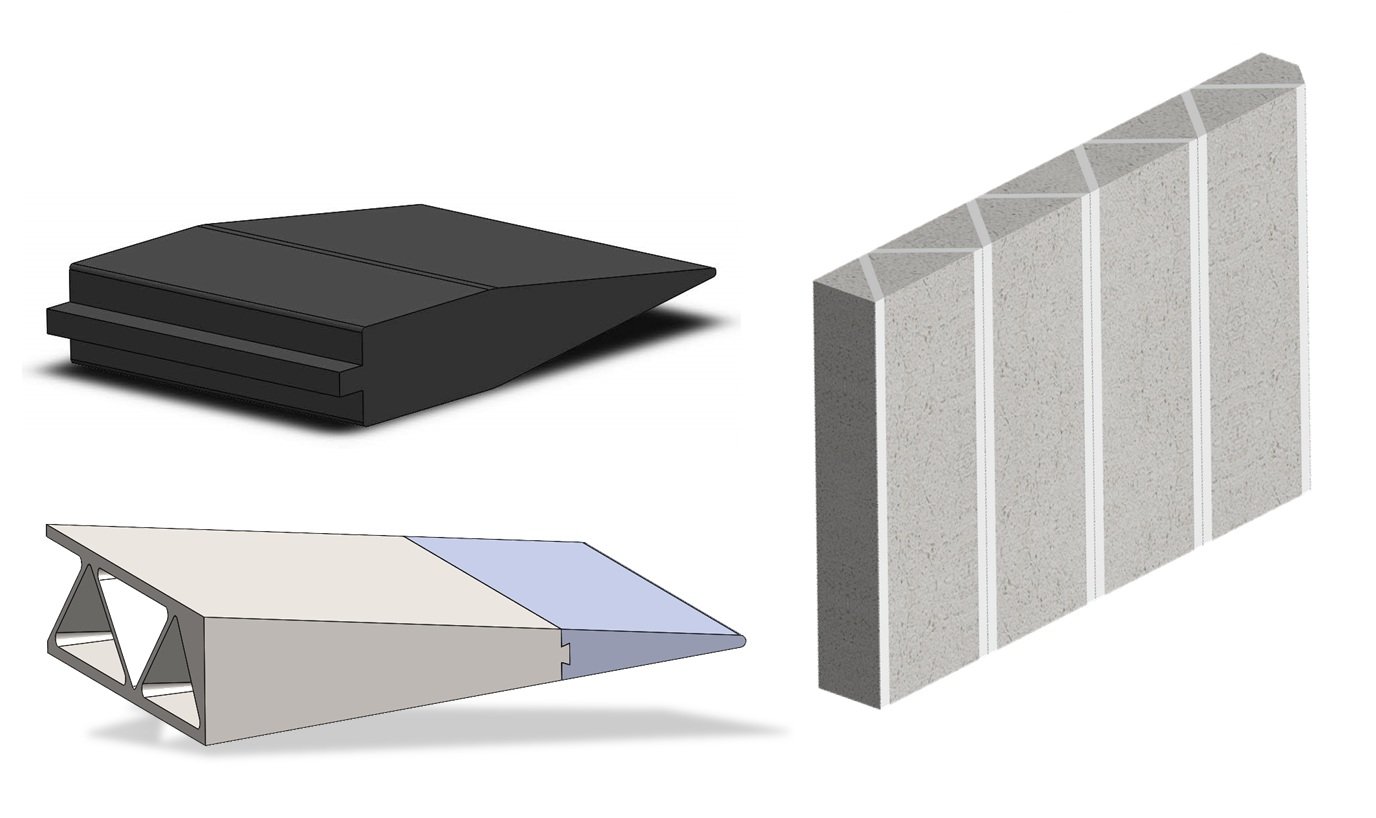

Harsher operating conditions and extended EM target frequencies are forcing new material and designs requirements for radomes, windows, and apertures. Hypersonic operation further limits available candidate materials. Additive manufacturing offers a route to rapidly prototype and develop newer, more complex layered and composite designs while simultaneously exploring hypersonic vehicle (HV) capable materials. Previous work at HAMR has demonstrated the ability to print low loss high temperature ceramics for RF applications, with high temperature dielectric measurements performed by our collaborators an Penn State. Combined with our modeling expertise, this enables a robust and efficient methodology to explore new radome, window, and aperture technologies.

Capabilities and concepts include:

Low loss carbide, nitride, oxide, and composite HV radomes

SWIR - LWIR transparent ceramic windows

Multimaterial AM designs (gradient, layered, patterned)

Hypersonic Materials

Hypersonic vehicles face numerous technical challenges, particularly for reusable military and commercial applications. Perhaps chief among them is the development of thermal protection systems capable of withstanding the extreme hypersonic environment. At HAMR, we believe additive manufacturing will play a key role in hypersonic vehicle and thermal protection system (TPS) development due to the ability to fabricate complex geometries from next-gen materials such as high entropy alloys and ultra-high temperature ceramics.

Capabilities and concepts include:

Refractory carbides for leading edge

Ultra-low density oxide insulators

Net shape composite ablatives

Refractory HEA/CCA and ceramic AM heat pipes

Solid Oxide Fuel Cells (SOFCs)

HAMR has pioneered a novel additive manufacturing strategy for the production of complete SOFCs in as little as three steps. There are several unique advantages inherent to this process, including:

Lower cost

Higher throughput

Improved performance

More complex designs

We are actively seeking partners to continue maturing this technology and transition into prototype scale testing.

Ceramic Matrix Composites (CMCs)

Ceramic matrix composites are a key technology in several aerospace and energy applications, however, development is slow due to the manual nature of fabrication and inherent variability of current processing methods. Additive manufacturing could enable a more automated production and rapid developmental cycle, however, several challenges face AM CMCs including: 3-dimensional strengthening, lack of continuous fiber, directional shrinkage, and efficient matrix generation.

Our goal is to utilize proven CMC fabrication processes based on high-efficiency polymer derived ceramics and transition these into an AM pipeline. Combined with a proprietary continuous filament and fiber alignment strategy, we aim to offer a major step in development of lower cost, more complex CMCs.

Rapid Prototyping Services

Looking to develop a new component using AM? Could AM improve the performance of a current part or your processing line? Contact us and let us help answer these questions!

Capabilities include:

Ceramic, polymer, and composite printing

Oxides, carbides, and common polymer materials

Ink, slurry, and process development

Part design and development